Are Custom Shoes Right for You?

If you struggle to find off-the-shelf shoes that comfortably fit your feet, custom footwear might be the right option for you.

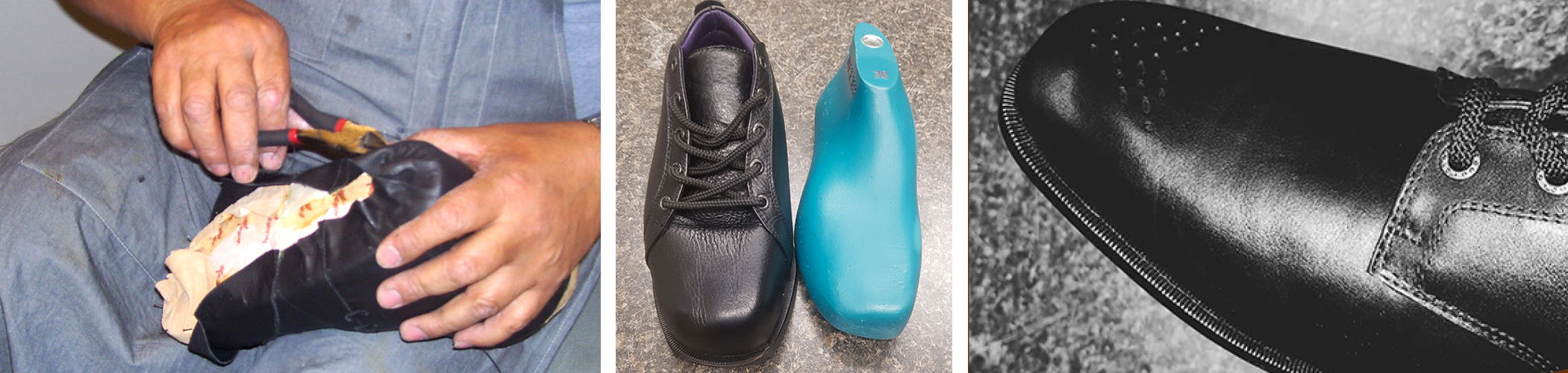

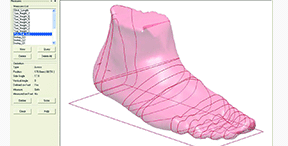

Elio’s specialists will begin the custom shoe making process by taking accurate and thorough measurements of your feet while also taking note of any foot abnormalities you may have. A 3D image of your foot and lower leg is then created using industry leading 3D scanning technology. The measurements are cross-referenced with the 3D image and used to create a last of your foot (also known as the shoe molds) for shoemakers to build your shoe around.

Elio’s specialists will then design the aesthetics of your shoe based on your desires. The style and materials of the upper, liner, and closure of the shoe will all be discussed, and made to your specifications. The midsole and outsole are created in-house at Elio’s Foot Comfort Centre to ensure they will properly control motion for your foot care needs.

Before your final shoe is made, a fit-trial shoe is created to ensure a proper fit and design. Any adjustments that need to be made are then sent to the shoemaker to be updated for the final product. Custom shoes from Elio’s are made by combining old world craftsmanship with new age technology so that your shoes look and feel amazing.

What is the last of a shoe? Why is it important?

The last is the heart of a shoe. It is the most impactful part of the shoe making process. A shoe last is a 3-dimensional wooden or plastic mold, which the shoe’s upper is built around. It affects the overall fit of a shoe. All lasts include the following dimensions:

Heel width

Instep height

Forefoot width

Toe box depth

Over foot length

Heel to ball-of-foot length

The measurements and 3D scans taken during your appointment are used to create a last specific to your foot. It is crucial to the custom shoe making process that the last is constructed properly as this is what will affect the overall fit and comfort of your custom shoe.

Elio’s 3-Step Process to Create Custom Shoes for You

1. Consultation

2. Measurements and 3D Image Creation

3. Fit Trial

4. Finished Product